Additive Manufacturing Americas Conference

It was a pleasure to speak about future additive applications in automotive production at the Am Show Americas 2017. Really enjoyed seeing old industry faces and connecting with some of the other speakers!

We're Two!

BDH is two years old! Since the first year was a lot of getting organized & getting our name out there, this was our first real full year of making clients dreams come to fruition, & it was awesome! Some highlights of the year:

- This year, clients & vendors have taken us all over the world (5 countries)!

- We've continued reinvesting profits in expanding our capabilities & bringing new technology in-house.

- We've had the pleasure of working on quite the variety of projects; from simple consumer goods to complex technologies that will greatly impact parts of the world.

Most importantly, I want to send a huge thank you to all of our clients, industry partners, vendors, & friends. As I was writing holiday greeting notes this year, I was elated to reflect on the amazing relationships that have graced BDH this year. The various Los Angeles communities that we're a part of have been integral in growing as a business. We are so thankful for the support, both locally & globally.

Much love,

Sam

Fashion Tech Forum 2017

We had a great time at Fusion Tech Forum with our friends from Inboard Technology.

With my friend Ryan Evans, Inboard Technology CEO.

Enjoyed some great talks from industry leaders.

Will.I.Am & the president of Flex, unlikely combo but interesting synergies.

Angela Ahrendts was my favorite speaker. Such a smart woman.

So cool to Nike implementing cutting edge technology in new product development. John Hoke is the head of design.

Fender CEO, Andy Mooney, gave a great talk about the future of technology in music education.

Tech In Motion Los Angeles TIMMY Awards 2017

It's always a pleasure attending Tech In Motion LA events. These guys do a ton for the LA startup community / Silicon Beach & they were nice enough to invite us back to exhibit at the TIMMYs again.

UploadVR /UploadLA hosted the event & they had some cool virtual reality, 360 cam, & full motion VR toys laying around.

We had to show off our SLA printing capabilities so this brush design was a trade show booth addition.

We went from idea to prototype on this in under 24 hours.

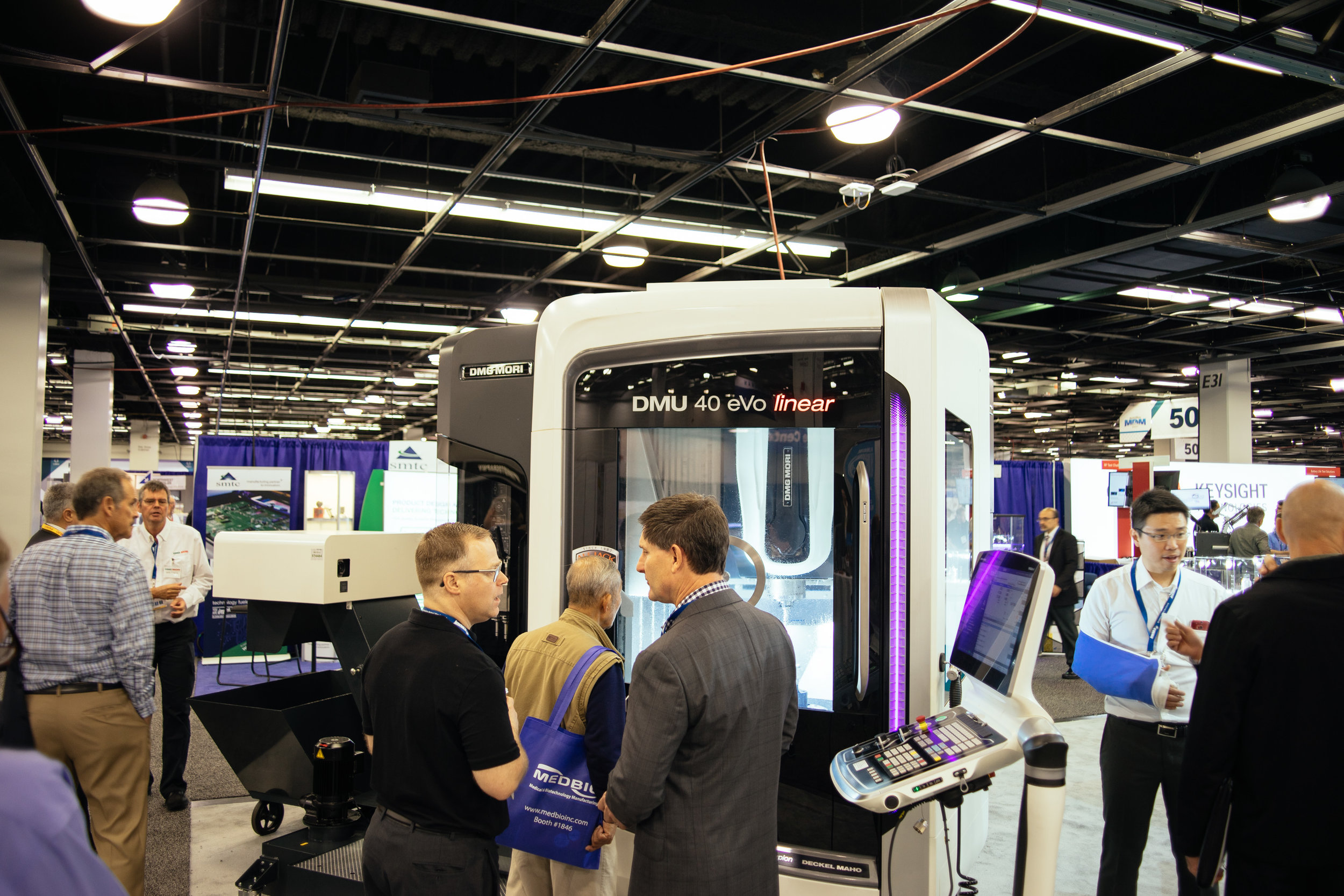

WESTEC 2017

We had a great time seeing the latest from some of our vendors & industry leaders at WESTEC 2017 (right in our backyard at the LA convention center). It's great to see the progress that additive / subtractive hybrid machines are making. The manufacturing world is changing & we align with those that are the first to invest in the future!

Happy I'm not the guy in charge of lugging these large machining centers from show to show.

Additive & subtractive 6061 material @ 99% dense!

Much love to Autodesk as always - these guys take care of us!

We Moved!

If you follow us on any social media, you saw we moved about a month ago! As we continue to grow in breadth & depth of capabilities, it's imperative that we have 1, enough space to work comfortably & efficiently, and 2, the infrastructure and facilities to maintain upmost security with trade secrets / intellectual property. Just a few blocks from our original location, the new home base checks both of these boxes.

In congruency with the move, we've added another cutting-edge prototyping tool to our arsenal; a SLA 3D printer with larger build volume! With this, we have the capability to precisely simulate and iterate a wider array of injection molded components with accurate surface quality & CMF.

2017 Q1 has been our best yet in all metrics & our future trajectory is set to contain some exciting highlights. It's an incredible point in time to be a part of the design & manufacturing industry.

Expo Week! SolidWorks World and UBM Advanced Design & Manufacturing Show

A fairly substantial chunk of my time is spent on technology research & industry forecasting; utilization of cutting-edge tech is embedded in our ethos. It also happens to be an area where I personally nerd out.. probably way to much. Anyway, Having Solidworks World literally steps away from our studio this year and the worlds largest design & manufacturing expo a short drive away, both in the same week, was pretty awesome to say the least!

At SolidWorks World, it was great seeing a lot of industry friends and showing face with quite a few of our vendors. The more intimate (relatively) venue allowed some great connections to be made. The food was pretty good too! Big thanks Autodesk for bringing us along.

Finally got to see one of these HP 3D printers in person. We really want one of these in house.

The J750 is undeniably one of the coolest 3D printers out there right now & we're lucky enough to have access to one! I've gotten some amazing multi-material multi-color parts from this machine.

Spent a good amount of time talking nerdy with NVIDEA, AMD, HP, & Dell and tried to finagle future product info from them.

This Markforged Metal X was to me, the most impressive additive technology at SWW. Interesting technology here but needs to mature a bit.

Of course it was great to see our friends from Haas!

I have a few friends at 3DSystems and they brought some impressive models out.

With rooms for Automation, Packaging, Electronics, Manufacturing, and Medical, the UBM Advanced Design & Manufacturing Show was HUGE! Unfortunately, I was running a tight schedule.. so outside of seeing some automation vendors from my old job at Tessy and meeting a few new contract manufacturers, the show was mostly a whirlwind of watching really cool machines.

Back when I was doing Robot End-of-Arm-Tool design at Tessy Plastics, these guys were our sensor supplier. Great to stay connected!

Robotic arms are advancing every year; cool to see the latest and greatest.

DMG is making some of the coolest machines there is right now. Additive / subtractive hybrids definitely have a bright near-term future.

We Just Turned 1!

Milestones like these are typically when company founders reflect back on highlights & accomplishments, praise their team, and project a positive outlook.

Our founding date is November 15th, 2015, but BRCHN Design House was many years in the making. The journey thus far is something I can't seem to summarize into a few paragraphs so I'll just say this: THANK YOU to our clients, and to everyone who has helped us along the way. We're just getting started & the future is bright.

- Sam

PS: In the interest of providing something along the lines of an earnings report:

Got to spend this afternoon crunching numbers. So so happy that my business is officially in the green after one year!

— Sam Birchenough (@sambirchenough) November 27, 2016

@sambirchenough well, last 3.5 years.. lots of ramp up before founding date.

— Sam Birchenough (@sambirchenough) November 27, 2016

We've expanded internal capabilities quite a bit (bought a lot of shit) & I can pay the last of it off now.

— Sam Birchenough (@sambirchenough) November 27, 2016

It's nice to be ever so slightly less fragile. We don't play it safe though, internalizing more processes & aggressive scaling ahead.

— Sam Birchenough (@sambirchenough) November 27, 2016

95% of rev was q3/q4 and my salary was just enough to not starve. All clients very happy.

— Sam Birchenough (@sambirchenough) November 27, 2016

Lets Talk $

Contrary to my usual highly visual posts, I’m going to hit you with a wall of text. Don’t bail just yet though because we’re going to discuss something everyone avoids: $.

I get calls daily from individuals with great ideas that they want to bring to market and I want to address some common misconceptions. To be frank, generally product development in the physical space is a complicated and expensive process. While we here at BRCHN Design House have ways to simplify industry norms and streamline the process, we aren’t magicians. Don’t get me wrong, I’m happy to get the calls and my business & passion are based around just that.

Let’s snapshot a few recent new-to-market products.

Dyson spent $71 million over the last four years developing their innovative, medium complexity consumer product; a hairdryer.

Nvidia spent “billions” of dollars designing their newest video card, the GTX 1080.

Both of these products made headlines because of their proprietary technology and huge development costs. While these examples may not be extreme outliers, they are certainly at the high-end financially. A lot of the inquiries I get are for ideas of similar size and complexity to the Dyson hair dryer. Speaking candidly, our pricing is somewhere between the best freelancers and large industrial design firms and our capabilities and results are on par with the best in the industry. That being said, I have yet to quote anyone at even 1/500th of the Dyson hair dryer development budget.

The big misconception from most individuals that call with their ideas is that a manufacture-ready design comes to existence quickly and easily. To give some insight here, I’ll summarize the traditional concept-to-market process (borrowing from a great post on Quora):

The process begins with you, the client, creating a Product Requirements Document (PRD). This is a description of what you want your product to be, and should include feedback from all departments; marketing, sales, users, etc. Even with all the preliminary work, it will still likely need to be expanded in more detail with us, the development team, but you should be able to come up with a good starting point on your own. This will be a living, breathing document.

If the technology is not a known entity, you will want to have domain experts (in Electrical Engineering Mechanical Engineering, Computer Science, etc.) reduce/develop the technology to a point where it can be commercialized. This can be a significant step for high-tech products.

From here, Industrial Designers will take the PRD, the technical limitations of the technology, and usability considerations, and distil them into some rough "blue sky" concept sketches, with a little bit of technical input from Mechanical Engineers and other experts. The number of concepts to be delivered is usually agreed upon in the contract. Also, depending on the nature of the product, rough models might be mocked up to aid in the evaluation of ergonomic considerations.

At this point, the concepts are shown to you, the client. You can choose to take these to customers, but often you will review them with resources internal to your company, or with a select few Subject Matter Experts (SME), Key Opinion Leaders (KOL), or some other marketing term for 'important people'.

Based on initial feedback, you down-select from the rough concepts; usually to 2 or 3. It is at this point also where you will notice specific details they had not considered before and express a preference. This often manifests itself in a "take the knobs on concept foam core A and the widgets from concept B and roll them into concept C" sort of conversation.

The concepts that have made the cut are refined further. This next round of concepts often has cleaner drawing, more consideration to manufacturing cost, assembly, technical feasibility, reliability, and other engineering factors. The designers may also create some 3D models to better communicate the geometry to the client. They may also create 3D models sufficient to be prototyped as appearance models. These appearance models can be used to show to users for feedback.

The concepts are presented and you down-select to one concept. Alternatively, you can discuss taking elements from one design and adding them to the other design. This would be discussed with the designers and engineers and evaluated for technical, ergonomic, and aesthetic efficacy. If it seems appropriate (and has been agreed to in the contract, or you’re willing to pay for the additional work), the designers and engineers will go back and refine the concept until all stakeholders are satisfied.

Usually it helps for the designers to create a 3D underlay to give the engineers a starting point, so the designers might do that.

From here the engineers begin to take over. CAD geometry is created (either off of 2D or 3D underlays from the designers) with considerations for manufacturing, shock and vibration, component placement RF shielding, weight, chemical resistance, ingress protection, fatigue, and other requirements.

As the CAD geometry is created, frequent prototyping is critical. As soon as a scheme is developed to accommodate the requirements alluded to previously, it should be physically prototyped. This can be expensive, but neglecting to truly solve high-level problems results in expensive detail work being done on a shaky foundation, with all the risk that such an approach entails (lots of it!).

From here it is just prototype and iterate until the requirements are achieved. This is the time frame where tradeoffs are often made. Aesthetic, usability, cost, schedule, and other considerations are all vying for attention, and sometimes the choices are mutually exclusive. This is a point where the PRD is worth its weight in gold. A clear understanding by all parties (from engineer to CEO) of what this product wants to be is necessary for clean execution of development. Changes to the PRD at this point can be expensive (both in money and time). It is up to you to determine whether a (to make a number) 5% drop in quality or increase in material costs is preferred over a 1-month delay in release date. This estimation may yield different results for products with a short sales cycle (consumer electronics) than those with a longer sales cycle (capital equipment).

Once the design meets all requirements, the team prototypes one more time. Even if it feels like you've just prototyped a week or two ago, there’s no better confidence boost than knowing that the exact design you are investing hundreds of thousands to millions of dollars in is the exact one that you have prototyped.

As the development process winds down, drawings will begin to be created. The level of detail of these drawings can vary (and of course is specified in the contract), but will usually contain the critical dimensions to be used for inspection, along with the tolerance of allowable variation of those dimensions. For some products, drawings often referred to as Critical to Function and/or Critical to Assembly documentation may be generated for the manufacturing vendor in order to provide quality control instructions for complex product parts or mechanisms. CMF (color, material & finish) documentation is often provided along with the technical documentation in attempt to ensure that the aesthetic design integrity is maintained. Many times, a Bill of Materials (aka BOM - the cost of producing each individual part at a certain volume) is also created for you and the manufacturer(s). There should be much back and forth between the engineers and the manufacturer(s) (and you, depending on level on involvement) so that no one is surprised by the drawings spec.

Once everything is designed and the documentation is completed, it's time to release for production. Get the circuit boards made, have the tools made to create the metal and plastic parts, get the OTS part on order, etc. Typically, the CMF specifications, BOM documentation, Critical to Function/Assembly documentation, 2D part drawings and the CAD database(s) are released at the same time to you, manufacturers, and vendors. Some combination of these items typically comprises the design package for the product - everything you would need to take the design to a manufacturer and have the product mass-produced. This information also allows the manufacturers to begin building tooling for the product.

Once the tooling is created, it's time to inspect the parts that come off the tools. This is called an FOT (First off Tool) inspection. During this inspection the engineer will check the parts against the drawing to ensure that dimensions are in the acceptable range, aesthetic considerations have been met, and so on. In the case of tolerances, statistical analysis can be used to extrapolate how many 'failures' per million will occur. If this number is unacceptable, the tool may be modified appropriately. The CAD databases may also be tweaked at this time to improve the cost efficiency and quality of the parts based upon the performance of the tool and the analysis of the FOT parts. There are other nuances as well, and they vary with the choice of manufacturing process used; suffice it to say that the people who designed the device need to be involved throughout manufacturing to ensure the integrity of the design is maintained.

Many times a limited number of "alpha" or "pilot" prototypes are constructed at this point. These prototypes are built from FOT parts and used for final functional, performance and technical testing in addition to being utilized for final aesthetic approval. Based upon the analysis of the alpha prototypes, tooling or CAD databases may need to be tweaked again and beta prototypes built or the design may be released for mass production.

Throughout preproduction, EVT, DVT, and PVT tests are conducted.

Engineering Verification Test: After the mechanical design is verified via mockup/prototypes, the tooling/molding can start. On the electrical side, the manufacturer would be preparing the materials for the production run of the first samples, including the PCB. These first samples would be used mainly for functional testing and basic performance testing. Not everything will be perfect here. Engineers will debug the bugs and modify the design for the next samples run.

Design Verification Test: Here, the basic functions should all work, and focus would be put on tweaking the design to optimize performance. More intensive testing would be performed at this stage, including environmental, reliability, compatibility, and other quality tests. This is to ensure that the product could work for a long time, at a variety of environment. It's also at this stage where samples would be sent out to pass regulatory tests to receive the necessary certifications (ie, FCC, CE, CCC, etc.) where you want the devices to be sold. At the end of this stage, all design bugs should be cleared and the design should be fixed.

Production Verification Test: This will verify a production ready stage. Here the focus is optimizing the production process; how to"multiply from one to many" the most efficiently, utilizing the best use of time and human resources, with the least failure rate. Quality assurance, industrial engineers, production engineers and others all work hard together to make this happen. A small-volume pilot run of a few hundred units would take place to test and optimize this process. At this point, you, the customer would usually be present at the manufacturer to audit everything and make sure everything is going according to the customer's standards and tastes. At the end of this stage, the customer would give the green light for mass production.Once all the parts are produced, they will need to be assembled and shipped. Some places will manufacture all the parts (machined metal, sheet metal, plastic, ceramic, electronics) and do all the assembly. This is rare. More likely you will have different parts made at different places. It is up to you to determine what you want to pay for. You can pay to have all your subassemblies and parts combined into a final product, or you can have the subassemblies sent to you where you can finish off the final product. This latter is often the case in high tech products, where the low-tech components are created elsewhere and the high-value element of the design is created in-house or at a trusted supplier.

Pheeeow. Quite a few steps! Luckily, at BDH, we have found ways to combine, streamline, omit, and expedite this process for most customer projects - so don’t feel overwhelmed! While I’m not going to share our exact process, you can check out this guest blog post on the Autodesk site to gain insight on some of the ways we differentiate by leveraging the latest design, prototyping, and manufacturing technology to yield process efficiency.

Everything from timeline to budgeting to planning is done on a per project basis so tell us about what you have in mind and we’ll let you know how we can help!

Founder Interview

Learn a little about how I got started in design and where I think its heading in this interview I did with Autodesk Education.