blurring the lines between art & science to create beautiful, functional products

Every client project begins by developing a unique framework guided by your product requirements, project goals, brand identity, design language, and manufacturing constraints. We then commence our highly optimized industrial design & mechanical engineering process, combining cutting-edge software & hardware toolsets with 15+ years of technical expertise and outside the box thinking. The result: beautiful, innovative products that make life better.

Design + Engineer

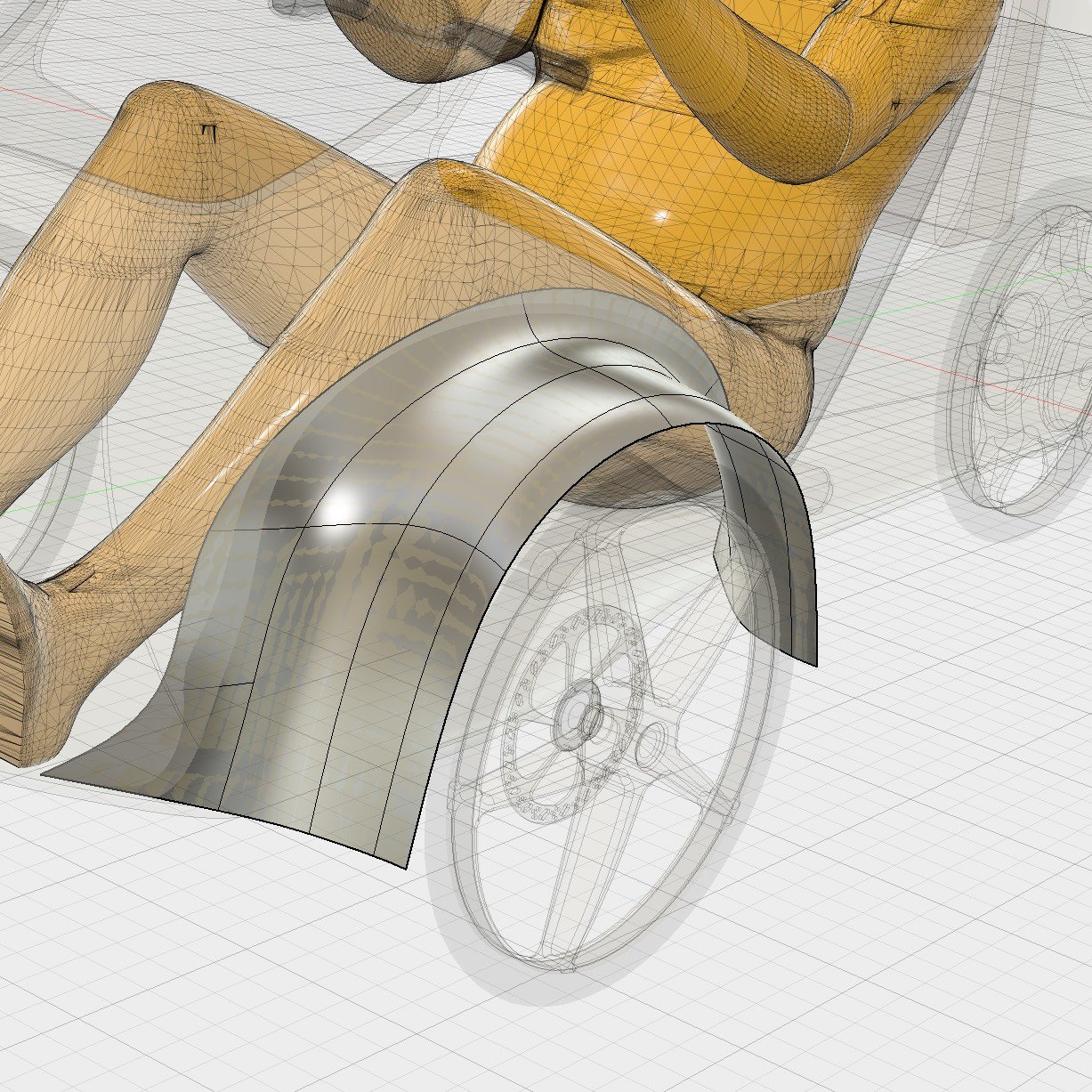

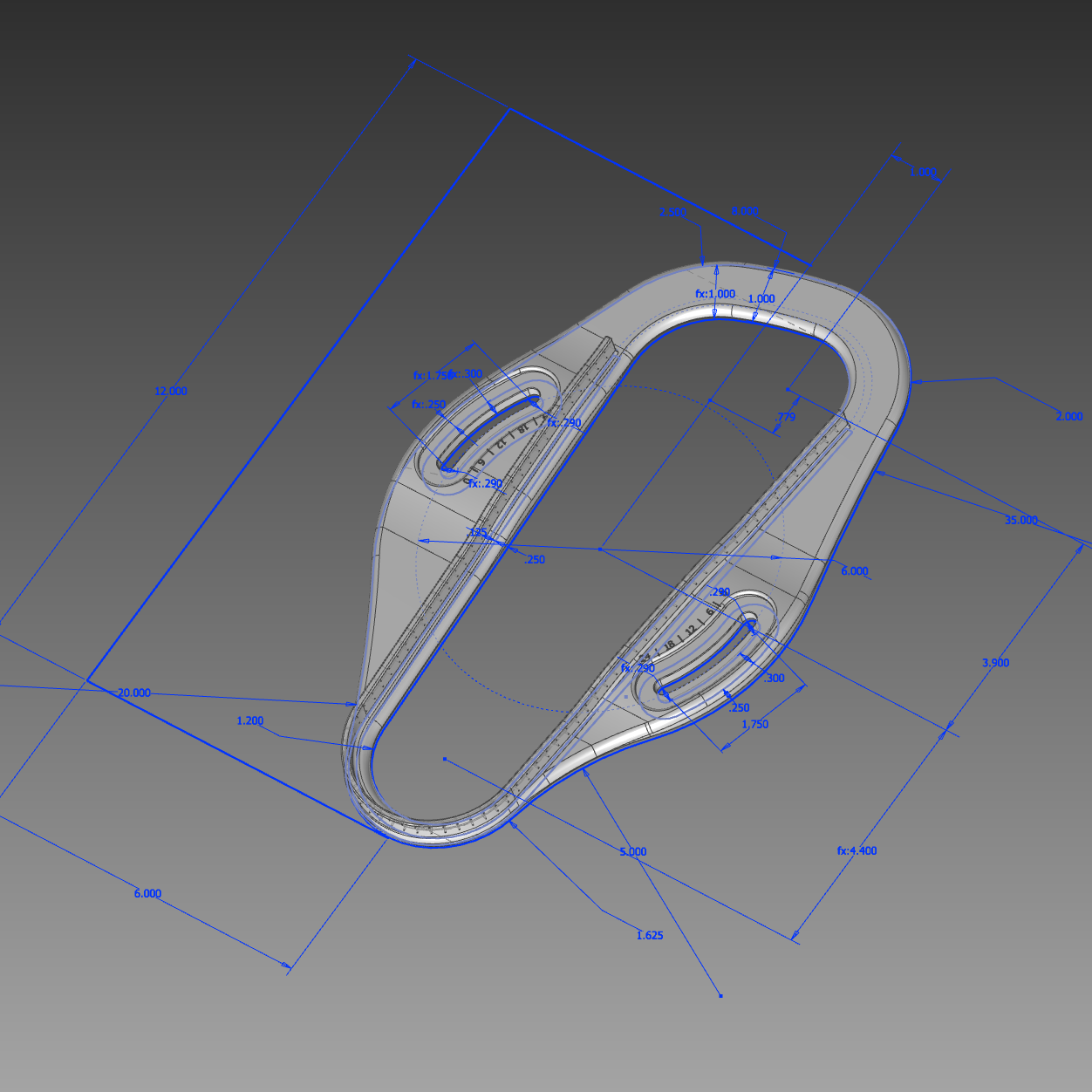

We’ve developed a unique top-down design approach, starting with 3D concept models & increasing in level of detail as we iterate and refine. The transition to volume production is de-risked with design for manufacturing consideration from the concept stage. We blur the lines between industrial design and mechanical engineering by working simultaneously in parametric and surfacing environments to create products free of traditional software limitations. Vast material property knowledge and use of simulation tools such as finite element analysis, computational fluid dynamics, thermal, modal, and CAM simulation lead to high accuracy when engineering for robustness and product lifecycle.

Render

Studio environments, scene environments, videos, and interactive animations. Nothing short of a prototype sells your idea like the highest quality photo-realistic renders. The combination of an advanced material library, expertise in lighting & camera, and a background in marketing & branding gives us the edge in rendering. Use these tools internally to sell investors & spec production texturing / CMF, or externally to beautifully showcase your product to clients.

Prototype

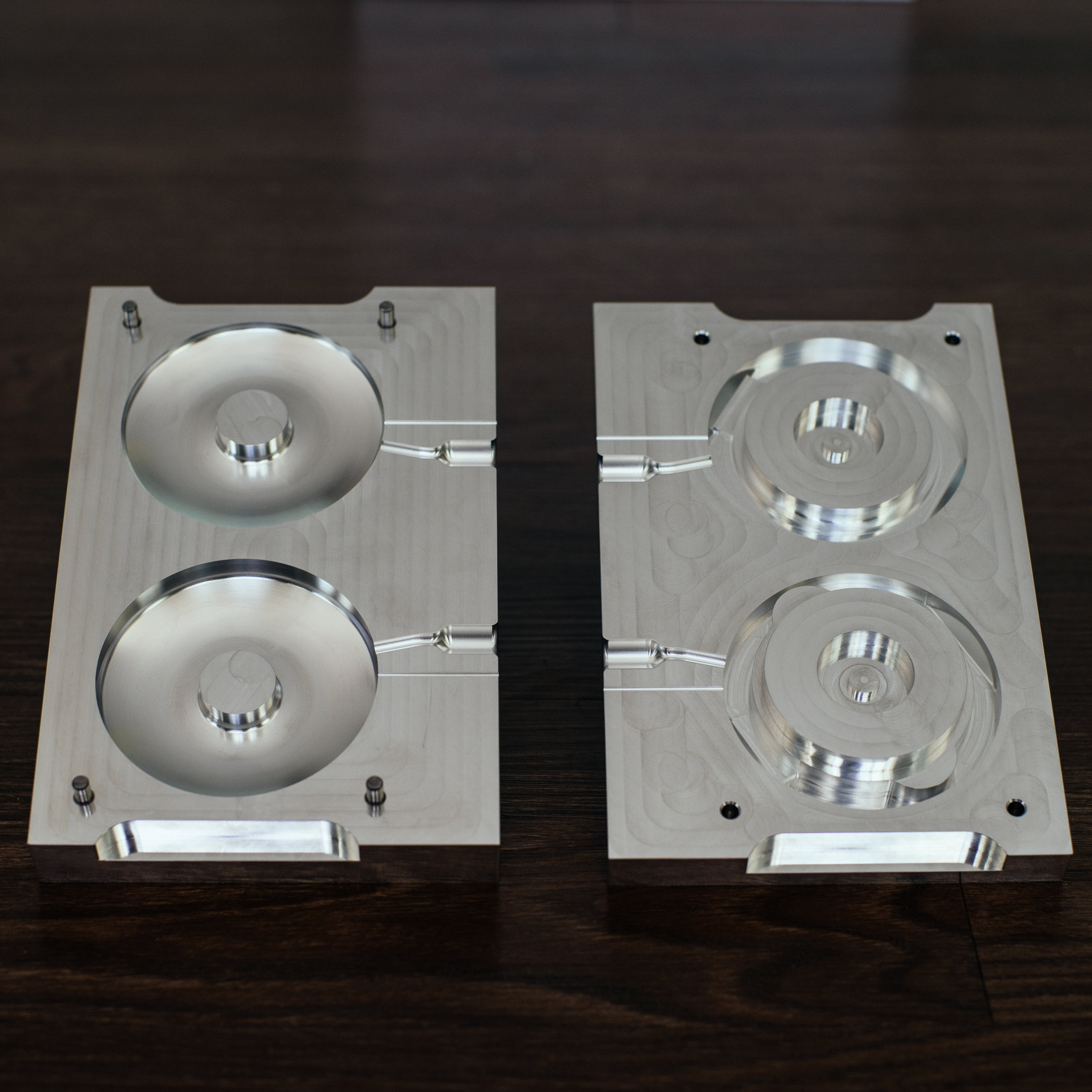

We maintain a consistently updated collection of the most useful rapid and traditional prototyping toolsets in-house for full control. Utilizing technologies such as our SLA (Stereolithography) & FDM (Fused Deposition Modeling) 3D printers, and CNC machine tools, we create functional and beautiful representative prototypes of your product in record time. Optimize user experience / user interaction. Validate assembly fit and system architecture. Experience your color, finish, and material choices pre-production. Having tangible product interaction in both form and function drives iterative design decisions and gives you confidence when it comes time to invest in manufacturing.

Manufacture

From communication to security, supply chain to shipping, tooling to packaging, manufacturing for hardware products is a complex landscape to navigate. We’ve personally vetted & established active long-term partnerships with leading contract manufacturers. Paired with expertise in optimizing designs for efficient manufacturing, this leads to a greatly de-risked ramp to volume production. Additionally, we have become the go-to design firm for a number of contract manufacturers.